Schneider ATV320U22N4C ATV | Variable speed drive, ATV320, 2.2 kW, 380…500 V, 3 phases, compact

21,280 EGP38,692 EGP (-45%)

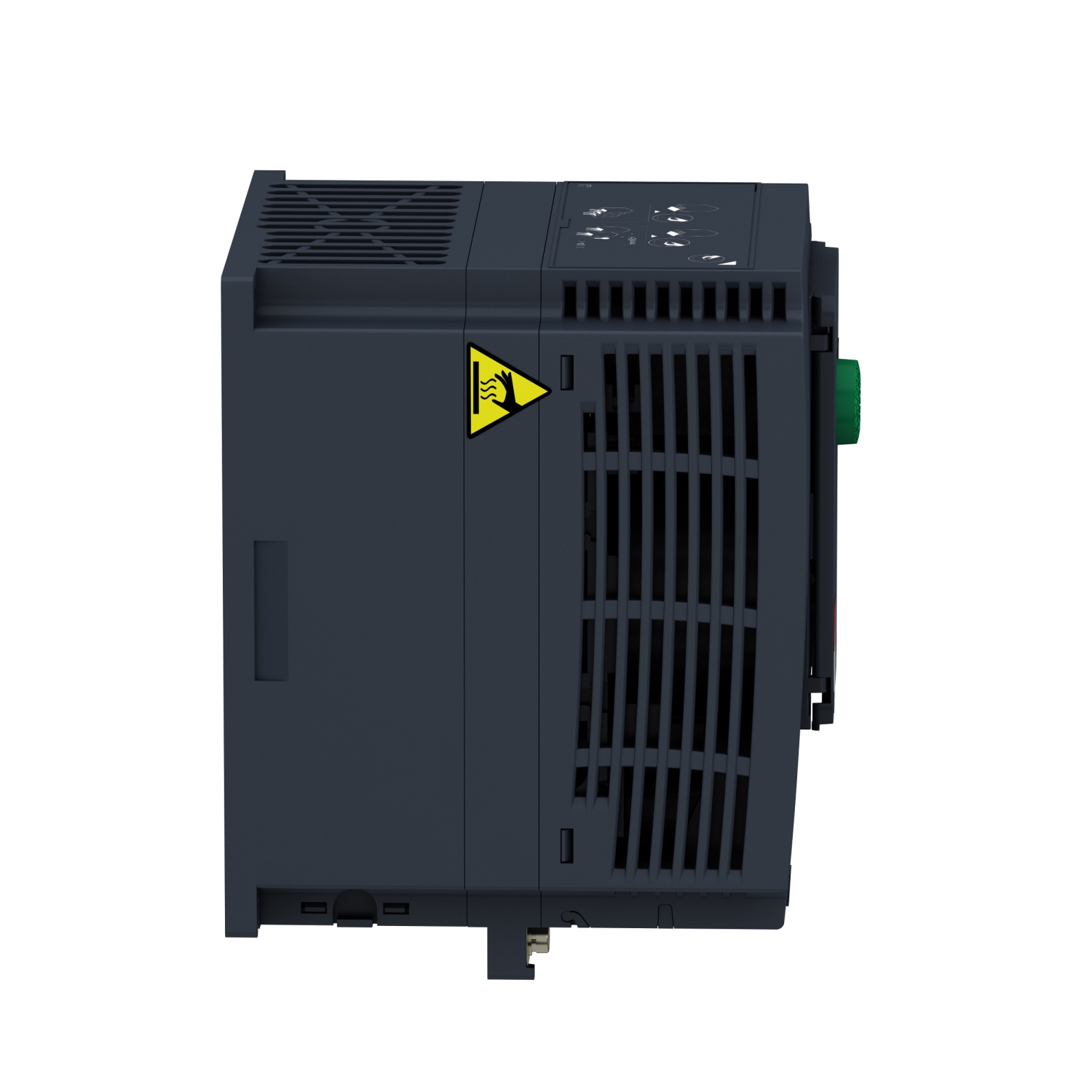

Schneider ATV320U22N4C ATV

Schneider ATV320U22N4C ATV: Power and Precision Combined

In the realm of industrial automation, having reliable motor control solutions is crucial for ensuring smooth operations and optimal performance. One such solution that has been gaining attention in recent times is the Schneider ATV320U22N4C ATV. Designed to deliver power and precision, this advanced variable frequency drive offers a range of features tailored to meet the diverse needs of modern industries.

High Performance Motor Control

At the heart of the Schneider ATV320U22N4C ATV lies its cutting-edge motor control capabilities. Equipped with the latest technology, this drive provides precise speed and torque control, allowing for seamless operation of motors across various applications. Whether it’s maintaining consistent speed in manufacturing processes or adjusting torque levels for optimal efficiency, this ATV delivers unparalleled performance.

Compact Design

Despite its powerful capabilities, the Schneider ATV320U22N4C ATV boasts a compact and space-saving design. Its sleek form factor makes it ideal for installations where space is limited, without compromising on functionality or performance. This makes it a perfect choice for applications where size constraints are a concern, allowing for flexible integration into existing systems.

Enhanced Safety Features

Safety is paramount in any industrial setting, and the Schneider ATV320U22N4C ATV is designed with this in mind. With built-in safety features such as overload protection, short-circuit protection, and motor phase loss detection, operators can rest assured knowing that their equipment and personnel are well-protected. This not only helps prevent accidents but also minimizes downtime and maintenance costs.

Applications of Schneider ATV320U22N4C ATV

The versatility of the Schneider ATV320U22N4C ATV extends to a wide range of applications, including:

- Industrial Automation: From conveyor systems to robotics, this ATV provides precise control over motor operations, ensuring optimal performance in industrial automation applications.

- HVAC Systems: With its ability to adjust motor speed based on demand, this drive is well-suited for HVAC systems, helping to enhance energy efficiency and comfort levels.

- Pump and Fan Control: Whether it’s maintaining water pressure or controlling airflow, the Schneider ATV320U22N4C ATV offers reliable control over pumps and fans, making it an ideal choice for building management systems.

Installation and Setup Process

Installing and setting up the Schneider ATV320U22N4C ATV is a straightforward process, thanks to its user-friendly interface and intuitive configuration options. With comprehensive documentation and support available, users can quickly get up and running with minimal hassle.

Programming and Configuration Options

The Schneider ATV320U22N4C ATV offers a range of programming and configuration options, allowing users to customize its operation to suit their specific needs. Whether it’s adjusting parameters for optimal performance or implementing custom control logic, this drive provides the flexibility and versatility required for diverse applications.

Maintenance and Troubleshooting Tips

To ensure the continued reliability and performance of the Schneider ATV320U22N4C ATV, regular maintenance is essential. This includes periodic inspections, cleaning, and lubrication of components, as well as proactive troubleshooting to identify and address any potential issues before they escalate.

Comparison with Competing Products

In a market saturated with motor control solutions, the Schneider ATV320U22N4C ATV stands out for its combination of performance, reliability, and ease of use. When compared to competing products, it offers superior features and functionality at a competitive price point, making it the preferred choice for many industrial applications.

Customer Reviews and Feedback

Feedback from customers who have used the Schneider ATV320U22N4C ATV has been overwhelmingly positive. Users praise its reliability, ease of installation, and robust performance, highlighting its role as a dependable solution for their motor control needs.

Pricing and Availability

The Schneider ATV320U22N4C ATV is available at competitive prices from authorized distributors and retailers worldwide. With widespread availability and comprehensive support, obtaining this advanced variable frequency drive is convenient and hassle-free.

Conclusion

In conclusion, the Schneider ATV320U22N4C ATV represents the pinnacle of motor control technology, offering power, precision, and reliability in a compact and user-friendly package. Whether it’s enhancing productivity in industrial automation applications or optimizing energy efficiency in HVAC systems, this drive delivers exceptional performance across a wide range of applications. With its advanced features, enhanced safety capabilities, and positive customer feedback, it’s clear why the Schneider ATV320U22N4C ATV is the preferred choice for discerning professionals in the field of industrial automation.

Additional information

| brands | Schneider Electric |

|---|---|

| Range of product | Altivar Machine ATV320 |

| Product or component type | Variable speed drive |

| Product specific application | Complex machines |

| Variant | Standard version With disconnect switch |

| Format of the drive | Compact |

| Communication port protocol | Modbus serial CANopen |

| Option card | Communication module, CANopen Communication module, EtherCAT Communication module, Profibus DP V1 Communication module, PROFINET Communication module, Ethernet Powerlink Communication module, EtherNe |

| Nominal output current | 5.5 A |

| Motor power kW | 2.2 kW for heavy duty |

| EMC filter | Class C2 EMC filter integrated |

| Height | 184.0 mm |

| Width | 140 mm |

| Depth | 158.0 mm |

| Net weight | 2.1 kg |

| Mounting mode | Wall mount |

| Network frequency | 50/60 Hz |

| Discrete input number | 7 |

| Discrete input type | STO safe torque off, 24 V DC, impedance: 1.5 kOhm DI1…DI6 logic inputs, 24 V DC (30 V) DI5 programmable as pulse input: 0…30 kHz, 24 V DC (30 V) |

| discrete input logic | Positive logic (source) Negative logic (sink) |

| Discrete output number | 3 |

| discrete output type | Open collector DQ+ 0…1 kHz 30 V DC 100 mA Open collector DQ- 0…1 kHz 30 V DC 100 mA |

| Analogue input number | 3 |

| Analogue input type | AI1 voltage: 0…10 V DC, impedance: 30 kOhm, resolution 10 bits AI2 bipolar differential voltage: +/- 10 V DC, impedance: 30 kOhm, resolution 10 bits AI3 current: 0…20 mA (or 4-20 mA, x-20 mA, 20- |

| Analogue output number | 1 |

| Analogue output type | Software-configurable current AQ1: 0…20 mA impedance 800 Ohm, resolution 10 bits Software-configurable voltage AQ1: 0…10 V DC impedance 470 Ohm, resolution 10 bits |

| Relay output type | Configurable relay logic R1A 1 NO electrical durability 100000 cycles Configurable relay logic R1B 1 NC electrical durability 100000 cycles Configurable relay logic R1C Configurable relay logic R2A 1 |

| Maximum switching current | Relay output R1A, R1B, R1C on resistive load, cos phi = 1: 3 A at 250 V AC Relay output R1A, R1B, R1C on resistive load, cos phi = 1: 3 A at 30 V DC Relay output R1A, R1B, R1C, R2A, R2C on inductive |

| Minimum switching current | Relay output R1A, R1B, R1C, R2A, R2C: 5 mA at 24 V DC |

| Method of access | Slave CANopen |

| Transient overtorque | |

| Maximum output frequency | |

| Motor slip compensation | Automatic whatever the load Adjustable 0…300 % Not available in voltage/frequency ratio (2 or 5 points) |

| Switching frequency | 2…16 kHz adjustable 4…16 kHz with derating factor |

| Nominal switching frequency | 4 kHz |

| Braking to standstill | |

| Brake chopper integrated | |

| Line current | |

| Maximum input current | 8.7 A |

| Maximum output voltage | |

| Apparent power | 5.7 kVA at 500 V (heavy duty) |

| Prospective line Isc | |

| Power dissipation in W | Fan: 74.0 W at 380 V, switching frequency 4 kHz |

| Protection type | Input phase breaks: drive Overcurrent between output phases and earth: drive Overheating protection: drive Short-circuit between motor phases: drive Thermal protection: drive |

| Standards | EN/IEC 61800-5-1 |

| Product certifications | CE ATEX NOM GOST EAC RCM KC |

| Marking | CE ATEX UL CSA EAC RCM |

| Pollution degree | 2 |

| Operating position | Vertical +/- 10 degree |

| Electromagnetic compatibility | |

| Volume of cooling air | |

| Overvoltage category | III |

| Regulation loop | |

| Speed accuracy | |

| Unit Type of Package 1 | PCE |

| Number of Units in Package 1 | 1 |

| Package 1 Height | 24.500 cm |

| Package 1 Width | 19.500 cm |

| Package 1 Length | 26.700 cm |

| Package 1 Weight | 2.652 kg |

| Unit Type of Package 2 | P06 |

| Number of Units in Package 2 | 12 |

Reviews

There are no reviews yet.