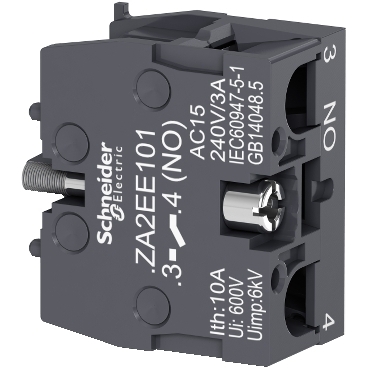

Schneider ZA2EE101 Harmony | Single contact block for head Ø22, 1 NO

62 EGP108 EGP (-42%)

Schneider ZA2EE101 Harmony

Schneider ZA2EE101 Harmony: Revolutionizing Industrial Automation

In the realm of industrial automation, efficiency and reliability are paramount. Companies are constantly seeking innovative solutions to streamline processes and enhance productivity. One such groundbreaking solution is the Schneider ZA2EE101 Harmony series, a versatile range of products designed to revolutionize machinery control and building automation.

Understanding the Harmony Series

The Schneider ZA2EE101 Harmony series encompasses a diverse array of products tailored to meet the evolving needs of industrial applications. From advanced control panels to intuitive interface devices, the Harmony series offers unparalleled performance and flexibility.

With its sleek design and cutting-edge features, the ZA2EE101 Harmony stands out as a flagship product in the series. Equipped with state-of-the-art technology, including high-resolution displays and intuitive navigation controls, it provides users with seamless access to critical information and controls.

Applications of Schneider ZA2EE101 Harmony

The versatility of the Schneider ZA2EE101 Harmony makes it suitable for a wide range of applications across various industries. Whether it’s industrial automation, machinery control, or building automation, the Harmony series excels in delivering superior performance and reliability.

In industrial automation settings, the ZA2EE101 Harmony serves as a central control hub, enabling operators to monitor and manage complex processes with ease. Its intuitive interface and customizable features make it an indispensable tool for optimizing efficiency and minimizing downtime.

Benefits of Using Schneider ZA2EE101 Harmony

The Schneider ZA2EE101 Harmony offers a myriad of benefits that set it apart from traditional control systems. Its unparalleled efficiency, durability, and versatility make it the preferred choice for industrial automation professionals worldwide.

One of the key advantages of the ZA2EE101 Harmony is its efficiency. By streamlining workflows and automating repetitive tasks, it helps businesses maximize productivity and reduce operational costs. Additionally, its rugged construction and advanced components ensure long-term reliability, even in harsh industrial environments.

Installation and Setup Process

Installing and configuring the Schneider ZA2EE101 Harmony is a straightforward process that can be completed in a few simple steps. Begin by carefully mounting the device in the desired location, ensuring it is securely fastened and accessible for maintenance.

Next, connect the necessary cables and power sources, following the manufacturer’s guidelines for proper installation. Once the device is powered on, use the intuitive setup wizard to configure settings and customize the interface to suit your specific requirements.

Troubleshooting Common Issues

Despite its robust design and advanced features, occasional issues may arise with the Schneider ZA2EE101 Harmony. Common problems include error codes, connectivity issues, and software glitches. Fortunately, troubleshooting these issues is a straightforward process that can usually be resolved with basic troubleshooting techniques.

If you encounter an error code, refer to the user manual for guidance on identifying and resolving the issue. In many cases, simply restarting the device or checking for software updates can resolve the problem. If the issue persists, contact Schneider Electric’s customer support team for further assistance.

Comparison with Competing Products

When comparing the Schneider ZA2EE101 Harmony with competing products, several factors come into play. These include features, performance, reliability, and overall value for money. In head-to-head comparisons, the Harmony series consistently outperforms its rivals, offering superior functionality and durability.

Customer Reviews and Testimonials

Real-life experiences from satisfied customers highlight the exceptional quality and performance of the Schneider ZA2EE101 Harmony. Users praise its intuitive interface, robust construction, and seamless integration with existing systems. Whether it’s optimizing production processes or enhancing building automation systems, the Harmony series delivers tangible results that exceed expectations.

Maintenance and Care Tips

To ensure optimal performance and longevity, regular maintenance and care are essential for the Schneider ZA2EE101 Harmony. Keep the device clean and free from dust and debris, and avoid exposing it to extreme temperatures or moisture. Additionally, periodically check for software updates and perform routine diagnostics to identify any potential issues before they escalate.

Future Developments and Upgrades

As technology continues to evolve, so too will the Schneider ZA2EE101 Harmony series. With ongoing research and development efforts, Schneider Electric is committed to introducing innovative upgrades and enhancements that further elevate the performance and functionality of the Harmony series. Stay tuned for exciting developments in the world of industrial automation.

Conclusion

In conclusion, the Schneider ZA2EE101 Harmony represents a paradigm shift in industrial automation, offering unmatched performance, reliability, and versatility. Whether you’re seeking to optimize production processes, streamline machinery control, or enhance building automation systems, the Harmony series is the ultimate solution. With its intuitive interface, advanced features, and robust construction, it’s no wonder that the Schneider ZA2EE101 Harmony is the preferred choice for industrial automation professionals worldwide.

Additional information

| brands | Schneider Electric |

|---|---|

| Range of product | Easy Harmony XA2 |

| Product or component type | Contact block |

| Device short name | ZA2E |

| contacts usage | Standard contacts |

| Positive opening | Without |

| Mechanical durability | 1500000 cycles |

| Tightening torque | 0.8 N.m |

| Contacts material | Silver alloy (Ag/Ni) |

| Short-circuit protection | 10 A fuse type gL conforming to IEC 60269-1 |

| [Ui] rated insulation voltage | 600 V (pollution degree 3) conforming to IEC 60947-1 |

| contact operation | Slow-break |

| Contact block type | Single |

| Protective treatment | TC |

| Standards | IEC 60947-1 IEC 60947-5-4 IEC 60529 IEC 60947-5-1 |

| Product certifications | CE CCC |

| Unit Type of Package 1 | PCE |

| Number of Units in Package 1 | 1 |

| Package 1 Height | 1.502 cm |

| Package 1 Width | 2.938 cm |

| Package 1 Length | 3.137 cm |

| Package 1 Weight | 0.014 kg |

| Unit Type of Package 2 | S02 |

| Number of Units in Package 2 | 200 |

| Package 2 Height | 15 cm |

| Package 2 Width | 30 cm |

| Package 2 Length | 40 cm |

| Package 2 Weight | 3481 g |

| Unit Type of Package 3 | PAL |

| Number of Units in Package 3 | 4000 |

| Package 3 Height | 60 cm |

| Package 3 Width | 80 cm |

| Package 3 Length | 90 cm |

| Package 3 Weight | 66400 g |

| Sustainable offer status | Green Premium product |

| REACh Regulation | REACh Declaration |

| REACh free of SVHC | Yes |

| EU RoHS Directive | Pro-active compliance (Product out of EU RoHS legal scope) EU RoHS Declaration |

| Toxic heavy metal free | Yes |

| Mercury free | Yes |

| China RoHS Regulation | China RoHS declaration |

| RoHS exemption information | Yes |

| Environmental Disclosure | Product Environmental Profile |

| Circularity Profile | End of Life Information |

Reviews

There are no reviews yet.